Enamel pins

Soft enamel pins

This is a typical method of pins.

Make an unevenness with a mold and pour enamel paint into the recessed area. Gradient expression is not possible, but it is possible to add color with the color specified by PANTONE.

Transparent epoxy resin can be placed on it to protect the surface and give it a glossy feel, and the texture of the finish changes depending on the presence and amount of it.

Epola / Imitation Cloisonné

Make unevenness with a mold, put enamel paint on the recessed part, dry it, and polish the surface with water. After that, buff polishing.

Because it is polished, the surface is flat and has a matte texture.

It is also called "Imitation Cloisonné", and it gives a luxurious finish like cloisonne. Since it is very resistant to deterioration over time, it is also recommended for lapel pins, emblems, and products that will be used for a long time.

Cloisonné / Hard Enamel

It is a traditional manufacturing method familiar in both China and Japan.

By glazing, baking at high temperatures, and polishing, you can obtain a beautiful finish with high surface hardness.

For color stability, cloisonne glaze is made in Japan.

with Printing

the range of expression can be expanded by combining it with printing. Printing is done on a lacquer topped with transparent epoxy resin. This makes it possible to express thin parts that cannot be colored, fine letters, and the character's face.

Printing

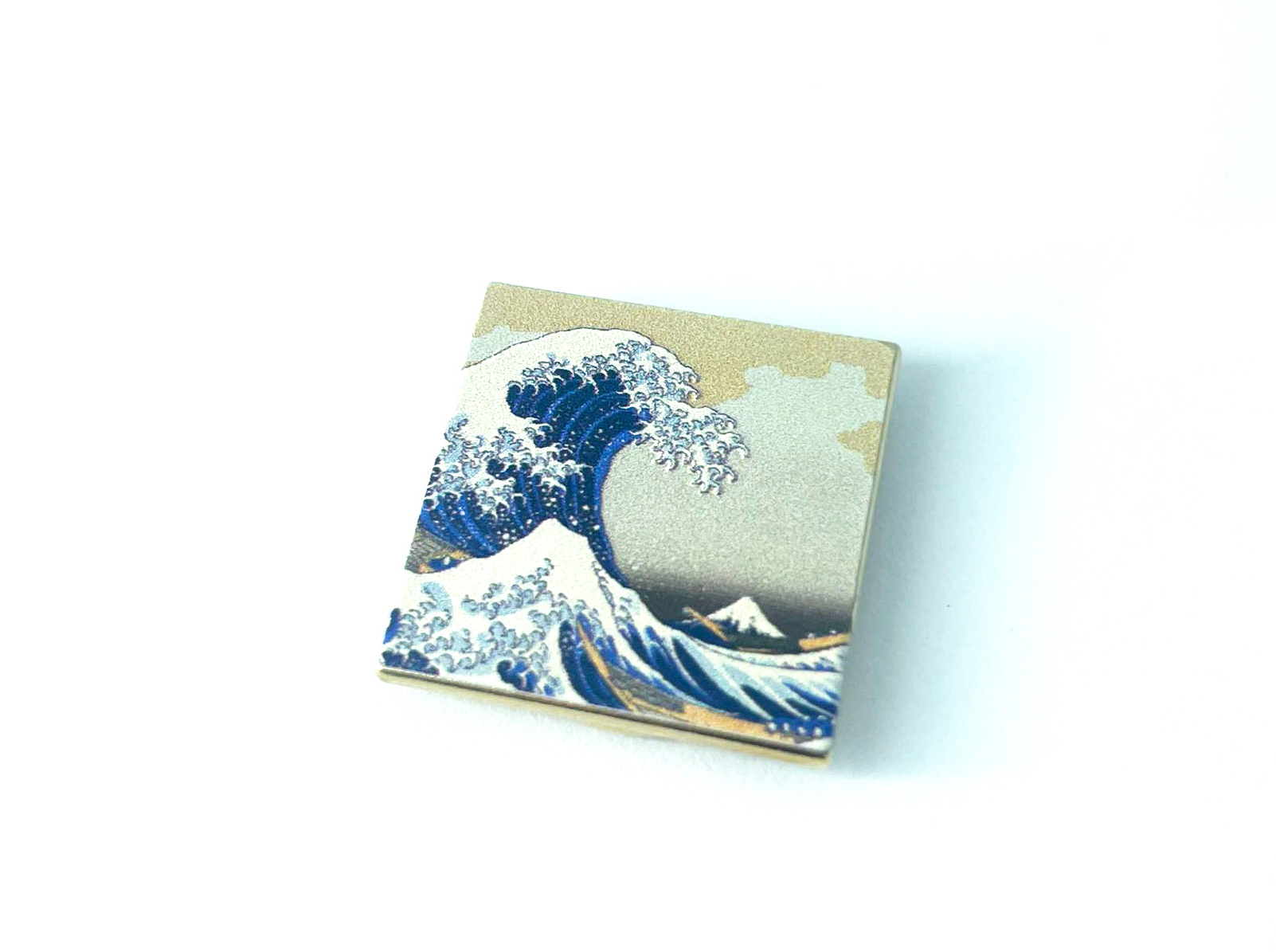

UV printing

Gradients and detailed expressions are possible.

You can reproduce the design without creating metal lines on the color borders. UV printing is often used in conjunction with other construction methods for small details such as letters and character faces.

It is possible to print to the edge, which is often recommended when you do not want to expose too much metal wire.

Offset Printing

It is the cheapest way to create a pins. However, since the cost of printing plates is required, it is a construction method suitable for projects with a large number of lots.

Silkscreen Printing

It has a matte texture and can be expressed in more detail than UV printing. It is recommended for creating company emblems, souvenirs, logos, etc. It creates and prints a plate for each color, so if you need a gradation, we recommend other printing methods such as UV.

Sticker Printing

A sticker printed in full-color 4C is attached to the pins body, and transparent epoxy resin is placed on top of it.

It is characterized by the fact that it can ensure the same printing quality as printing on paper.

色入れ+印刷

組み合わせ - 色入れ+印刷

色入れだけでなく、印刷と組み合わせることで表現の幅が広がります。ラッカーに透明エポキシ樹脂をのせた上に印刷を行います。これにより、細くて色入れができない部分や細かい文字、キャラクターの顔などを表現できるようになります。

Other

Relief

It is a construction method used for

company emblem. The range of expression is increased by making the convex part glossy and the concave part being sand ground texture.

Semi-solid

The mold is made semi-three-dimensionally and applied to UV printing. It can be printed to express fine details, and it goes well with illustrations because it is rounded. It is recommended when you want to create an item with a special feeling.